Problem/Need

Among

the 10 major artisanal groups in India, potters

comprise the fourth largest but second poorest group

with an estimated 10 lakh people directly or indirectly

involved in this vocation. Despite the existence

of a stable and consistent demand for a narrow range

of pottery-ware, these traditional potters are in

a deep crisis due to severe competition from industrial

products like plastic and aluminium goods. They

are unable to met this challenge since there has

been a drastic depletion of raw materials, as suitable

clay becomes more and more scarce, while there is

no innovation or upgradation of their skills and

technologies. Attempts to alleviate their lot through

providing technological inputs remained largely

unsuccessful since merely mechanizing some processes

may lead to increased productivity but the shrinking

market remains a fatal bottleneck.

Range

of Products

Approach/Strategy

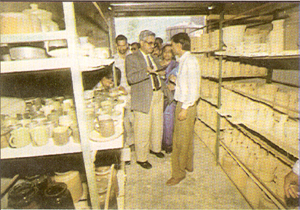

In

order to resolve this problem a countrywide study

of production practices of potters and in-depth

R&D work was conducted with the help of CGCRI

and several VOs. This led to the evolution of a

technology package, which successfully resolved

the problems of poor quality and depleting white

clay resources by developing a protocol of admixtures

for red-clay and appropriately scaled machinery

for clay processing. As a result, the potter can

now utilize the commonly found red-clay for making

excellent quality glazed-ware obviating the dependence

on costly white clay. Moreover, with the introduction

of this new technology, the product range of the

potter expands, and thus the dying trade can be

rejuvenated. The salient features of this technology

package are:

-

Suitable treatment, processing and admixture

techniques for upgradation of the quality if

common or red-clay.

-

Matching non-toxic glazes.

-

Appropriately scaled machinery for use by potter

groups.

-

New type kilns for fuel efficiency and reduction

of breakage.

-

Innovative product range including tableware,

decorative items and construction material.

-

Low cost bone-ash preparation for bone china.

-

A system-design incorporating clusters of potters,

using the technology package, and producing

the innovative product range with suitable marketing

strategy.

-

Data base on diverse clay types, quality upgradation

protocols, technical and economic features of

clay-based artisanal production and social dimensions

of artisanal pottery.

|